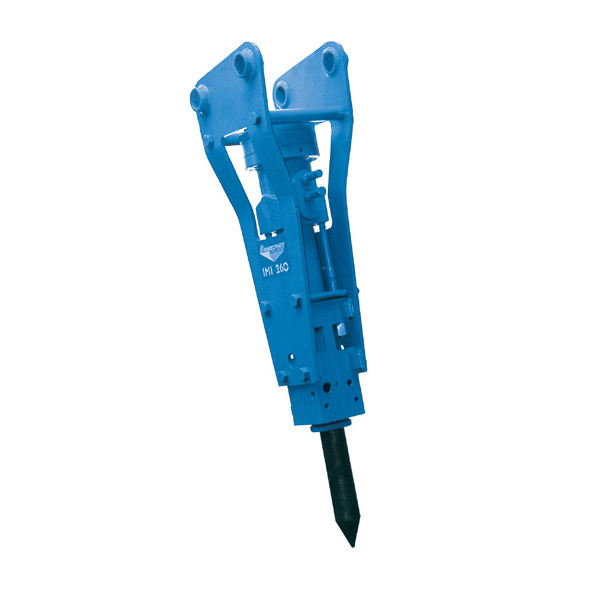

Use

PREMISE: the IMI range is made up of mainly 20 models, available in a variety of versions, with an operative weight ranging from 80 to 3000 KG suitable for big or small excavators, backhoe loaders and other carrier machines with weight from 0,7 to 50 tons.

Use IMI 260: Mounted on midi-excavators and backhoe loaders or backhoes, used for a great variety of works, versatile, especially in inhabited areas, with respect to the limits of noise and vibration emissions in the environment.

Hydraulic Breakers that belong to this category are suitable when mounted on arm booms of crushing plants to break big blocks of rock and considerably reduce the size of rocks close to the mouth of the crusher. They are also mounted on radio controlled excavators, wherever the site does not allow human presence, hence remotely controlled even with the help of remote cameras.

Customizations

The IMI range can also be equipped for under water uses.

The IMI range is also available in silenced versions, particularly appreciated for works located in city centres.

SELF LUBRICATING SYSTEM

* upon customers’ requests the IMI Hydraulic Breakers can be provided with a special self lubricating system, that requires no additional installation on the excavator.

The system is placed directly on the hydraulic breaker and it works thanks to the vibration and blows of the hydraulic breaker itself.

Thanks to flexibility and versatility, the company provides a number of special versions of the same models, all customizable.

Advantages

Premise

IMI Hydraulic Breakers are supplied with a tested operative system that makes its maintenance easy and cheap, considerably reducing delays caused by downtime.

Advantages

- High productive performance of the Hydraulic Breakers

- Low vibration level:

Less stress transmitted to the carrier’s arm, to the operator and on the environment and adjacent structures.

(the Hydraulic Breakers are dampened hydraulically by means of a diaphragm with nitrogen and also mechanically through special rubber shock absorbers).

- All new models of the IMI range are particularly fit for new machines.

(equipped with hydraulic pressurized systems)

This means that the Hydraulic Breakers can tolerate high backpressure, a lot better than previous models.

* Important:

It is also possible to provide top brackets and quick hitches that can be mounted on any type of excavator.

What else do we offer you?

40 Years Experience

Specialized since 1975 in design and manufacturing of Hydraulic Breakers and other quarry and demolition equipment.

100% Made in Italy

Highest Quality

All our Hydraulic Breakers, Products and Spare Parts areamong the most reliable on the market.

ISO-9001 Quality Certified Company System

Contacts WhatsApp

Contacts WhatsApp